Stratasys Ltd. unveiled new technologies and partnerships with heavyweights Siemens, Boeing and Ford Motor Co. in a move that could accelerate the 3-D printer's prominence in lightweight auto and aerospace parts manufacturing, company officials said.

Stratasys CEO Ilan Levin told investors and trade writers from eight countries Tuesday at the Crowne Plaza Bloomington that from now on Stratasys would rely on partnerships with industrial customers to help solve manufacturing problems, drive innovation and grow the company.

To that end, Levin introduced what he called "game changers" — technologies that can make industrial-strength but lightweight parts for cars and planes and can print parts in extremely large sizes for the first time.

The Infinite-Build 3-D Demonstrator — made to satisfy specifications from Boeing and Ford Motor — can seamlessly print large lightweight components that are the size of a building or the length of an entire airplane.

The new Robotic Composite 3-D Demonstrator combines Stratasys' advanced 3-D printing composite materials and extrusion capabilities with Siemens' motion control hardware and product management software.

The new machines also speed up the painfully slow 3-D printing process by about tenfold. Officials emphasized that the new technologies introduce a new phase of "additive manufacturing" for the auto and aerospace industries, but declined to disclose development costs or say when or how much revenue will be generated by the new technologies.

If successful, however, analysts said the new partnerships and products might help struggling Stratasys gain marketshare in the competitive 3-D printing marketplace and also make some money. Stratasys, which lost $1.4 billion last year and has lost $41 million for the first half of this year, is recovering financially after years of heavy technology investments and after one bad and costly stumble in the consumer 3-D printing realm.

Forty investors were bused Tuesday from the Bloomington hotel to Stratasys' Eden Prairie U.S. headquarters to see Stratasys' new machines in action. While investors snapped away cellphone picture and videos, the new Robotic Composite 3-D Demonstrator rotated, changed axis and continuously spiraled, laying molten composites into various patterns without stopping and without using traditional chopped up plastic filaments. That seamless capability differs from regular 3-D printing methods that deposit chopped strings of molten plastic in straight lines.

Company officials said the new robot and Stratasys' evolving line of industrial- strength composites should have widespread appeal to the aerospace, automobile, medical and oil manufacturing sectors. The new 3-D printing technologies will debut before 115,000 attendees next month at the International Manufacturing Technology Show.

Levin said the machines offer customers a new level of factory integration, automation, speed and monitoring capabilities. They are "catalysts for the transformation" of the industry.

The computerized machines, which read and print from computer-aided design and drafting (CADD) software files, are flexible and should let factory customers make or "print" their own manufacturing tools and production "set up" stations as well as make parts at a much faster rate than was previously possible.

The Infinite-Build model also solves another problem.

Until recently, Stratasys and most other U.S. 3-D printing firms have been hamstrung by the traditional method of 3-D printing plastic parts inside printer boxes, or "envelopes," that were not quite 5 feet wide. That restricted the size of parts that could be made.

With the new technology, Mike Hayes, Boeing's head of additive manufacturing, said he envisions a day when Boeing can use Stratasys' technology to seamlessly 3-D print the entire wing of an airplane with lightweight materials. He added that Boeing is not there yet, but that such a feat would be an industry "holy grail."

For now, Boeing is using an Infinite-Build 3-D Demonstrator to produce low-volume, lightweight parts, Hayes said, while holding up a large panel made of hollow plastic honeycombs and a rocket-duct made of a fiberglass-like material.

"These are so light," he said. "It's pretty cool."

Ford Motor officials said they expect to use the Infinite-Build to make manufacturing tools, or "jigs," for the company's auto factories. It also will probably make production parts for a few of its specialty prototype cars, said Ellen C. Lee, the director of Ford's Additive Manufacturing Research Department.

There are no plans to use Stratasys' new equipment to make full production Ford vehicles, she said. However, Ford and Stratasys will work together to test and develop new applications and see if they can create automotive-grade 3-D printed materials not previously possible.

Stratasys is similarly working to make stronger composites that can withstand the heat of rockets, jet fuel and the forceful pressures of flight and space.

Arun Jain, Siemens' vice president of motion control, and Andreas Saar, Siemens' vice president of manufacturing solutions and additive manufacturing, said Siemens worked with Stratasys for years to lend Siemens' expertise in robots, automation and computerized manufacturing to the 3-D printing world.

Going forward, it expects to use the new composite-laying robot to help solve a number of problems for Siemens' own customers.

"It's quite an opportunity. And we look forward to continuing to work with Stratasys to build manufacturing solutions that transform industries," Jain said.

Stratasys' stock rose 64 cents per share to close at $23.17 Wednesday.

Dee DePass • 612-673-7725

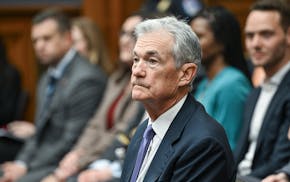

Fed's Powell: Elevated inflation will likely delay rate cuts this year

Participant, studio behind 'Spotlight,' 'An Inconvenient Truth,' shutters after 20 years